Wealth Success

Mitsubishi Worm Gear Reducer

Mitsubishi Power Transmissions

Mitsubishi Worm gear

unit

Mitsubishi Planetary traction drive unit

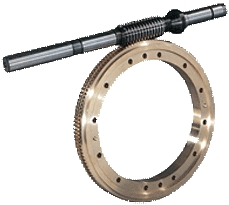

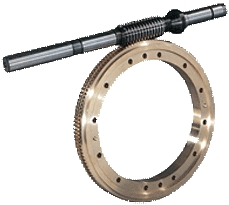

Mitsubishi Worm gear set

Mitsubishi Dual lead worm gear set

Mitsubishi Worm gear unit Basic information Field of cutting-edge technology that demands high-level reliability like for semiconductor manufacturing equipment is out home ground. Mitsubishi's technlogy evolces further the Niemann tooth profiles. Mitsubishi's worm gear units contribute to energy saving. Main Feature High load capacity The worm and worm wheel mesh with each other on concave and convex surfaces. This increases the relative radius of curvature and reduces stress on the tooth surface, thus raising relative transmission capacity. Worm wheel tooth thickness can be increased without weakening worm strength, giving the teeth higher bending strength. High efficiency, long life The line of simultaneous contact between worm and worm wheel forms a nearly 90¡ãangle in the direction of motion, facilitating the formation of a lubricating oil film between the teeth surfaces, for higher transmission efficiency. This film also reduces abrasion, resulting in longer tooth life. High reliability The excellent performance characteristics of Mitsubishi worm gears are available in wide range of worm gear units, all offering superior efficiency and reliability. High maintainability As easy handling cylindrical worm is employed for quick, simple assembly and maintenance. Separate worm gear sets (worm and worm wheel) are available for specific applications.

Mitsubishi Planetary traction drive unit Basic information Realization of low noise, low vibration and rotational accuracy that break through the boundary of gears. Mitsubishi is a top runner in the traction drive technology. Our products are highly reputed in the fields of cutting-edge technologies, including the digital image processors, ultra-precision machine tools, film manufacturing and coating equipment. Mitsubishi is sole supplier of traction drives that enable larger torque transmissions. (Max. 6,000 Nm) Main Feature High rotational accuracy (Minimum speed irregularity) Planetary mechanism composed of rollers produces smooth rotations and eliminates the speed irregularity due to the high frequency inherent to gear transmissions. Zero backlash, ultra-precision positioning accuracy Transmission by rollers being contacted under pressure allows to eliminate the backlash so that ultra-precision positioning can be achieved in the full closed loop controls. Low noise/low vibration Since the movement is produced by the rotation of rollers, it produces a capacity that breaks through the boundary of gear transmissions.

Mitsubishi Worm gear set Basic information The worm gear set is favorably accepted in the field of precision machine tools. Mitsubishi's technology evolves further the Niemann tooth profiles. Mitsubishi's worm gear sets contribute to energy saving. Main Feature High load capacity The worm and worm wheel mesh with each other on concave and convex surfaces. This increases the relative radius of curvature and reduces stress on the tooth surface, thus raising relative transmission capacity. Worm wheel tooth thickness can be increased without weakening worm strength, giving the teeth higher bending strength. High efficiency, long life The line of simultaneous contact between worm and worm wheel forms a nearly 90¡ãangle in the direction of motion, facilitating the formation of a lubricating oil film between the teeth surfaces, for higher transmission efficiency. This film also reduces abrasion, resulting in longer tooth life. High reliability The excellent performance characteristics of Mitsubishi worm gears are available in wide range of worm gear sets, all offering superior efficiency and reliability. High maintainability As easy handling cylindrical worm is employed for quick, simple assembly and maintenance. Separate worm gear sets (worm and worm wheel) are available for specific applications.

Mitsubishi Dual lead worm gear set Basic information High precision worm gears with minimum backlash in which Mitsubishi's technical expertise is condensed for use on mother machines. This set is favorably accepted in applications to precision machine tools, various positioning devices and precision feeders. Mitsubishi merchandized the dual lead worm gears initially. Main Feature High precision /minimum backlash At every process of designing, machining and inspection, we strive to break though the boundaries of high precision and minimum backlash. Simple principle for backlash adjustment Backlash is adjustable to optimum state just by moving the worm shaft in the axial direction. High rotational accuracy Minimum error on the gear and low mesh frequency suppress the fluctuation in rotation to an extremely low level and enable high precision transmissions.